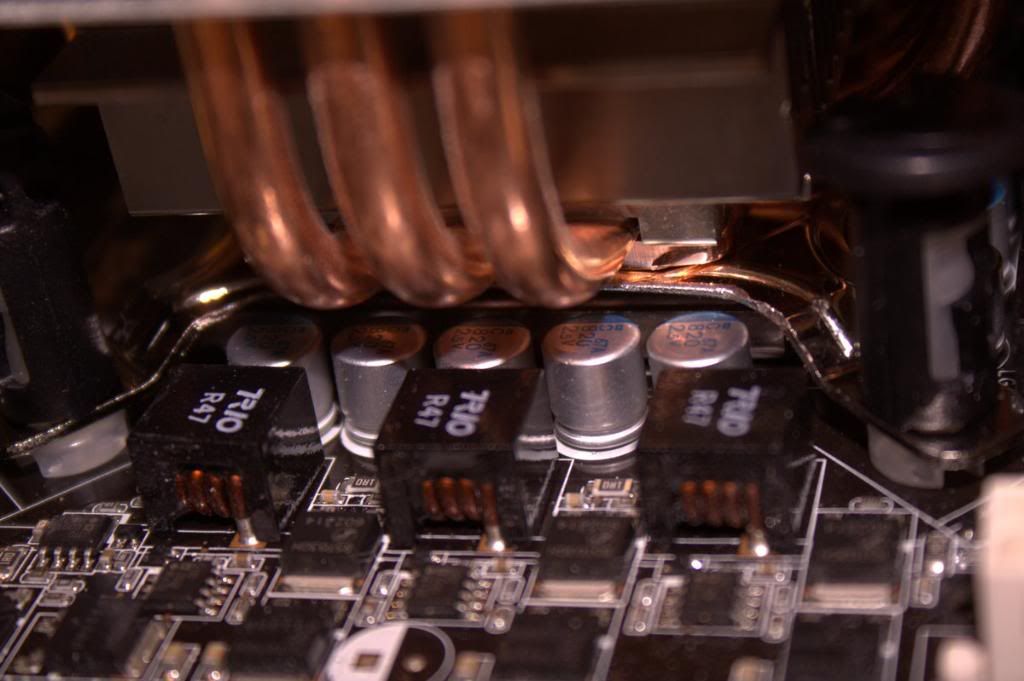

When they mounted the Ninja onto the P5B at the store, I didn’t question it. But when I started looking at SPCR I saw that a lot of people had mounting problems, and when I looked closely, I saw that the mount was pressing down on a line of capacitors.

So. Part 1: Adapting the mount to fit the motherboard.

I tried to get tin snips on a suggestion here at SPCR to trim down the mount. The guy at Home Depot who tried to snip the mount suggested instead a heavy duty file. So I bought a 'Nicholson Black Diamond' file.

About 30 minutes of filing while cooking dinner on the BBQ resulted in this:

You can see it sitting on the motherboard - it sits flat now.

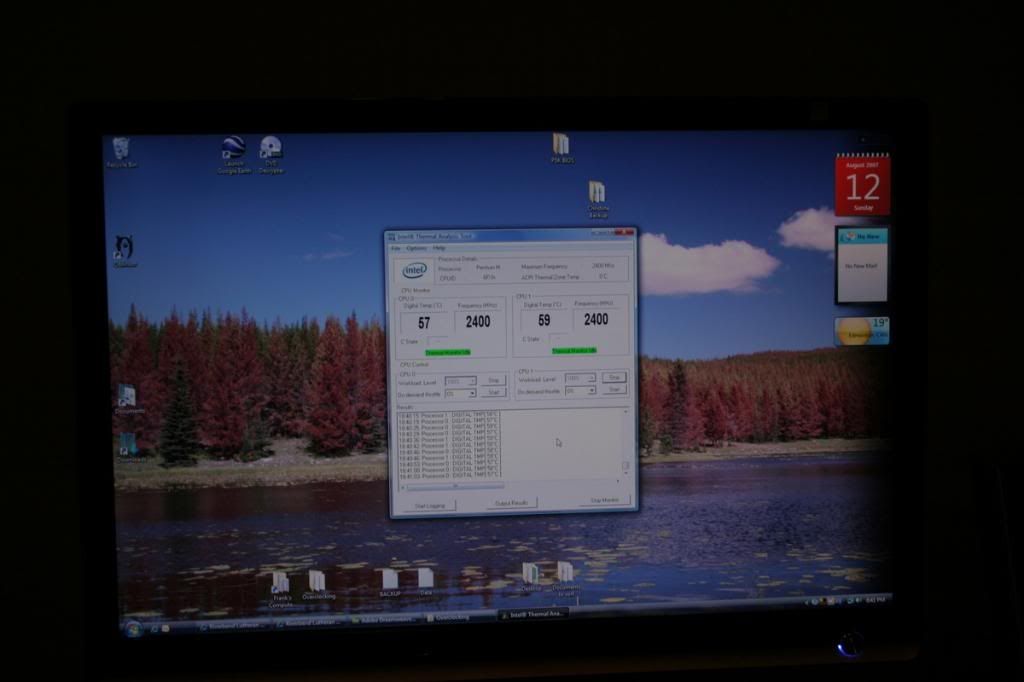

I remounted the Ninja with the plastic mounts into the Antec Solo. It seemed to help but still nothing too fantastic. The power supply fan continued to ramp up immediately and the system still idled at 47C and loaded at 59C (stock E6600).

(Idle)

(TAT 100% Load)

---

On to Part 2: The case swap and Ninja re-mount.

A couple of weeks ago I bought a bunch of YL fans and a Thermalright bolt-through kit from jabtech.com (which is a great place).

I was sick of my fan being so loud, and I was sick of the really cheap case on my second computer so I bought an antec p182b and a Corsair HX520 to rebuild my system with. My old SOLO and OCZ case went to the server as a nice upgrade.

Top: old computer in the SOLO. Bottom: the P182b

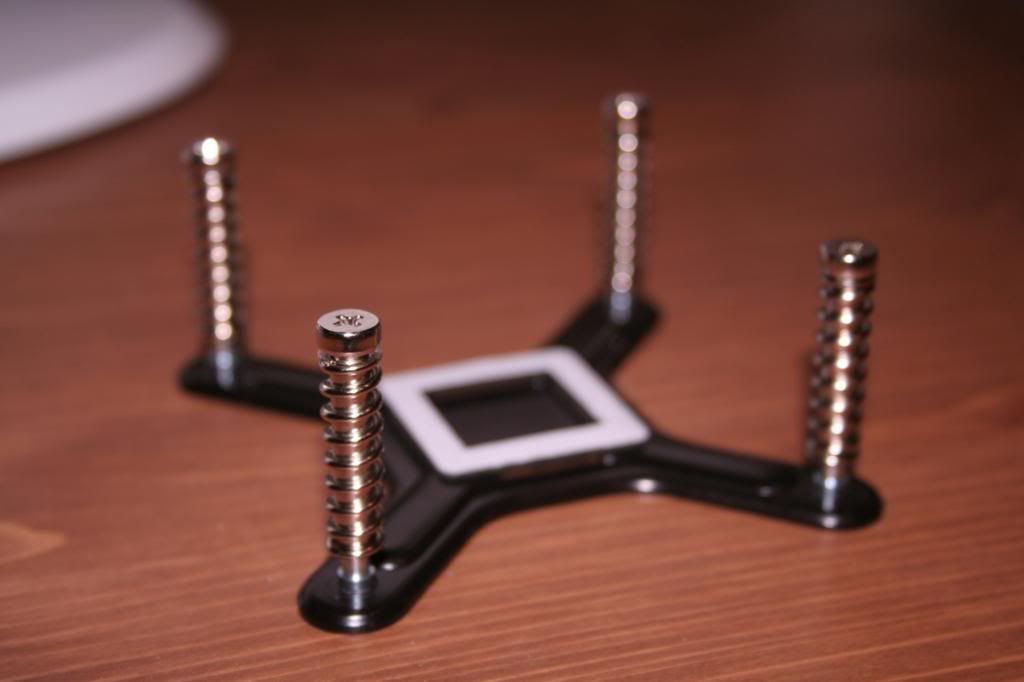

The thermalright bolt-through kit

The Mojito I was drinking...I made a lot of these that night.

The disassembled computer

Step 1: remove CPU. Whoops, there's a hair on it!

Step 2: clean it and the Ninja

Step 3: Prepare to mount the Ninja - this is how it will go on

Step 4: Mount it. I had a HECK of a time with this. The backplate was centered beneath the motherboard, the Ninja rested on top, and I had to reach my fingers in to twist each screw. The screw is spring loaded and the springs aren't held in place, so often when I thought I was twisting the screw, I was just spinning the springs.

I Eventually had to use a really long screwdriver to reach down through the Ninja to screw them into place. The screwdriver was the wrong size so I had to press really hard and guide with my fingers.

Note: The first screw goes in okay but the second one (opposite side) you really have to push the heatsink down with one hand while screwing it in with the other. It's hard. Really.

Mounting the heatsink took me the better part of an hour. My advice: get a really long screwdriver that will go down the length of the heatsink tower and screw it in from the top.

It's finally done.

The backplate.

The finished product. It's under a table so I don't have the best angle.

My Nexus hard drive enclosure holding the Raptor. Can you see it?

Results: Much quieter, even when the PSU fan spins up (playing Oblivion). The raptor idles quietly but that never really bothered me - what bothers me now is the *really* loud seeks that vibrate the whole case. I think I will replace the nexus in the 5.25" slot with a suspension system for the raptor.

All in all a success though - my temps dropped from 47/59 (idle/load) to a much better 37C idle, 48C load. Ambient temp around here is about 24C.

Part 3 is still to come, and it involves upgrading my motherboard to a Asus P5K, and moving the Asus P5B motherboard and the 3 storage drives to the second computer to use as a file/web server. I just bought a house though...so I'm kinda out of money.

Thanks for listening. Hopefully this helps to encourage Ninja use - the bolt-through kit cost 6 bucks and (once its on) works like a charm.

Mark