The side duct on Sigma One consists of a circular perforated section on the side panel, with a plastic, "garnish," ring outside and the extendable duct on the inside. The exhaust of the case had your typical punched grill. I decided to buy a set of Wiss tin snips and cut those grills out, to improve air flow. Being that the very, very quiet fan spins at such low speed, I figured that cutting the grills would probably help some, so I completely cut out the exhaust grill, and then I completely cut out the perforated sheet blocking the intake duct and completely removed the center portion of the intake shield so it's wide open.

Boy, I sure underestimated how important killing grills is.

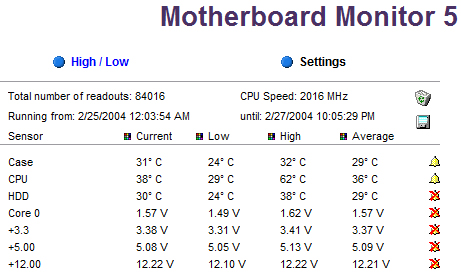

These were my before temps:

62C peak temp after a couple hours of Prime95 High Heat Test. That is actually decent, considering I don't have a fan mounted on the CPU HS.

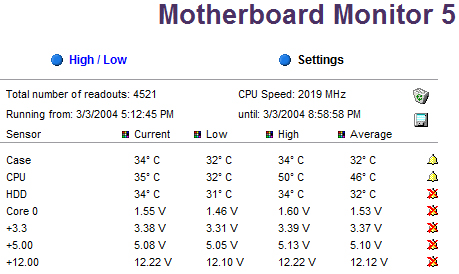

And these were my after temps:

The peak temp, after a few hours of Prime95 High Heat Test, is now only 50C.

Ladies and gentlemen, that's a 12C drop in peak temp, just buy cutting out some grills; talk about kick-ass!

I must admit, again, I never expected such incredible results. I knew the intake duct was restricted, but I never expected such a dramatic improvement; maybe 5C at best. My only explaination is that the duct is the only intake in the system, it all blows right onto the HS of the CPU, and then gets the hot stuff sucked straight out the back. I actually feel much more air coming out the back with my hand now.

All in all, a worthy bit of effort.

-Ed

EDIT: Typos, as usual.

More EDIT: Formatting and grammar.