Edward Ng:

Gooserider; was adding to my last reply by edit when the e-mail came in notifying me of your post; will address it after this:

---Copied & Pasted as PS from last reply---

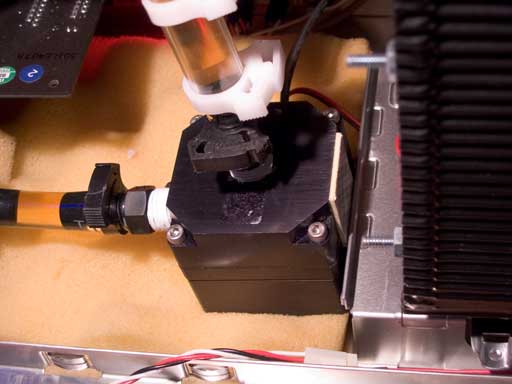

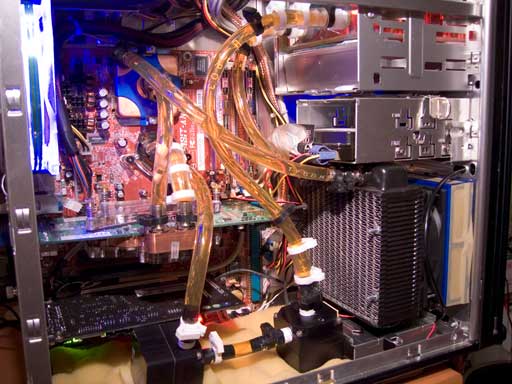

I do not feel the need to address the other stuff in this thread. My system itself is not the primary focus here, as has been discussed before. It's not about Ed's water setup. It's about what happens when you run two CSP-750s instead of just one, and what happens when you switch from two pumps in serial to two pumps in parallel.

Agreed, (oops, gotta pause, GF is groping me....

) (a considerable while later - Sorry Ed, some things are just more fun than your WC system...

) At this point, barring problems suggesting that you are bottlenecking on the rad size, changes don't make much sense.

I agree on the air flow being backwards; I've read that it should pull through and I'm sure it works better, but I did not have time to screw around any more with the heatercore assembly--I wanted to get this show on the road already. Same goes for trying to fit in a larger heatercore; when I get the time and energy to bust up more of my case to cram in some uber ultra extreme gigantor heatercore from a Peterbilt, fine, I'll do it, but not now, not until this circuit comparison is done, because it just isn't pertinent to the test. As it is I plan to change out the duct for a better one; considering how much trouble it will be to undo the RadBox now that it's sealed up with box tape inside and out, I'm not doing it untul it's time and I'm not going to make minor changes when that time comes.

Makes sense. Mostly my suggestions have been aimed towards future mods, not anything that needs to be done now. Since you've started to run tests and generate numbers, changing anything but the pumps would be bad as it would skew the results.

I do not wish to discuss tube diameter; 3/8" was much easier to work with, and every single part of my cooling setup uses 3/8" fittings. Considering the blocks I chose, 3/8" is perfectly adequate. Had I blocks designed for 1/2" instead, I'd have considered going 1/2". There's no way I'm going bigger than 1/2" and I do not see any reason to. Using 3/4" tubing when all your blocks aren't even designed for anything over 1/2" is ludicrous. The minor improvement improvement in performance is not worth the nightmares in routing, fitting, adapters etc. etc. to use something like that. Do you think that using 1/2" tubing would change whether or not dual pumps is better than single? Would it change the results comparing serial to parallel? I doubt it.

Given the 3/8" fittings the use of 3/8" hose is reasonable. OTOH, it does represent some level of restriction, and that restriction WILL be significantly greater w/ serial pumps and higher head pressures. IMHO there is no reason to even consider larger diameters in most of a normal system - the only place I'd even consider it would be for the link between the res and the pump inlet to ensure no inlet restriction (See Phaestus' article on Net Pump Suction Head over to ProCooling). I'd also consider it if doing a really complex multi-box setup like Airspirit's for the manifolds but not in the system itself. @WC pressures and flows the benefits are negligible.

Whether or not the northbridge needs cooling under such extreme overclocking conditions has been under debate before, is currently still under debate, and will likely be under debate forever. I'm not going to delve into that at this time. Needless to say, the block was relatively cheap, and the heat it introduces into the system is peanuts compared to the CPU or GPU.

Agreed on the debate, and also that the heat added is negligible. IMHO the issue w/ NB cooling isn't with the cooling as much as it is the added plumbing complexity, flow restrictions, etc. *I* don't think it's worth it, but am not fanatical about it, there is a case for both stances.

Quieter fan? Sure--the day I decide to water cool this system for silence without headphones on my head.

---End Paste---

Again agreed, changes are for later. Might be interesting though to do it as a "typical WC system being quieted" sort of article.

Obviously we've reached a concensus that the heatercore/fan assembly can be left alone for the time being (assuming it does not heavily affect the test outcome). That's nice.

Okay, fine. No set duration. When it appears stabilized, that's it. Whether it's 2 hours or 48.

Not sure I agree on that... I am not sure the time is critical in setting the initial parameter, but I do think that once a time has been set, it should be consistent. At the very least there should be a requirement that "stable" is a set of temps that has been maintained w/o significant change for some consistent and considerable time (1hour?). It might also be worth noting how long it took to get to a stable temp, especially if this varies.

If your concerns about heatercore capacity limiting my test results turn out true (i.e. the results for all three arrangements are, within margins of testing error, the same), then consider the test null and void. Sorry, but I did my best, unless somebody else is going to foot me the cost of a better heatercore (in that case I'll just set it up outside of my case with a minimal tube run, run the full battery of tests on the 3 pump arrangements, and then call it that). How much more can you ask of someone who's a first time water cooler and has a massive backlog of other reviews to take care of (I have samples of Cooler Master CoolDrive 6, Aerogate 3 and Ultra Vortex all sitting around begging for attention)?

I have one core I could possibly do a short term loan on, but you'd need to pick up the freight, and I'm not sure it would be worth UPSing it back and forth.

I have seen the early numbers you posted, and I think it is pointing towards a system bottleneck somewhere that is keeping you from doing better. I suspect it is the core's ability to reject heat, although it could also be a block limit (less likely). The idea of doing a test like this is a reasonable one, but it does point up the limits of system level testing in that the effects of the other components in the system tend to mask the variable. This is why I tend to prefer isolated tests like BillA's where efforts are made to ensure that the rest of the testbed has enough capacity that only the varied part will have an impact. (he would also be grumbling about your level of accuracy, etc. but we don't need to go there now. However it is worth noting that accurately measuring WC gear poses the same sort of problems that getting dB #'s for really quiet components does - Zeroes are ALWAYS expensive numbers...)

While you have done a wonderful job with what you have, especially for a first time WC effort, I don't think your results are all that useful since they reflect all of your hardware, and other choices might have different results. For instance your blocks do quite well at low flows; while they do better with higher flows, a Cascade would have shown a bigger difference. Etc, Etc, each change makes a difference and there are no magic bullets. The key is choosing parts so as to create a balance where each component contributes at it's optimal point on the returns curve. This is not an easy thing to do. Given YOUR components, I suspect that a single pump is your optimal point, and adding a second pump won't make a big difference.

Gooserider