Cooling Processors quietly

Moderators: NeilBlanchard, Ralf Hutter, sthayashi, Lawrence Lee

-

graysky

- Posts: 147

- Joined: Fri Sep 16, 2005 4:14 pm

- Location: My desk

Post

by graysky » Tue Jul 17, 2007 1:17 pm

When my Ultra-120 X and I have to say I'm a little puzzled. The base where it should contact the heat spreader is not smooth at all, it's actually grooved! You can see a scratch which is where I gently ran my thumb nail over the surface; I could feel the rough edges.

Have a look for yourself:

Anyway, others encouraged me to lap it which I've never done before. After wrestling with the idea for a couple of days as well as reading many articles/guides, I decided to give it a go. Plug:

wrote a great guide for HS lapping.

$20 worth of sandpaper, a $2 piece of flat glass, and 4 hours of careful work (and sweat) later, I was left with a pretty darn flat HS. You can see by the pictures that this particular one was quite concave instead of being flat which isn't good for keeping contact between the HS and IHS of the CPU.

Did it work you're probably wondering. The temp data as measured in [url=http://www.almico.com/speedfan.php]speedfan.exe for a ~1 h x264 encode (uses all 4 cores with a CPU load of >99 %). I had speedfan log the temps (which it does every 3-4 seconds) and I averaged the whole data set per core for the 2nd pass of the 2-pass encode (the 2nd pass is the most CPU intensive). Room temp for both experiments was ~23 °C. By the way, I added a constant of 15 to each core in speedfan since it incorrectly displays temps for quads by 15 °C.

System specs: Q6600 @ 9x333=3.01 GHz (stock voltage), P5B-Deluxe in an Antec p182 case.

Code: Select all

Before lapping the HS:

Core 0: 66.9

Core 1: 66.4

Core 2: 60.6

Core 3: 60.6

After lapping the HS:

Core 0: 64.9

Core 1: 64.4

Core 2: 59.0

Core 3: 59.4

Delta:

Core 0: 2.0

Core 1: 2.0

Core 2: 1.6

Core 3: 1.2

-

Bluefront

- *Lifetime Patron*

- Posts: 5316

- Joined: Sat Jan 18, 2003 2:19 pm

- Location: St Louis (county) Missouri USA

Post

by Bluefront » Tue Jul 17, 2007 2:19 pm

That first base picture does look pretty bad. I usually go up to 1500 grit when I lap something. I start with 800, but if I had a heatsink as bad as your's, I might have started at 400.

But you left out one important item......if your CPU has a heat-spreader, it needs to be lapped also. Those things are almost never flat. Lapping one is a bit more tricky, but the procedure is similar. I always use machine cutting oil during any lapping....as a lubricant. And I change the sand-paper constantly during the process......

-

graysky

- Posts: 147

- Joined: Fri Sep 16, 2005 4:14 pm

- Location: My desk

Post

by graysky » Tue Jul 17, 2007 2:26 pm

Right you are... I actually lapped it a few days later and wrote up the whole experience in

this thread.

-

zoob

- *Lifetime Patron*

- Posts: 380

- Joined: Tue Apr 13, 2004 7:12 pm

- Location: Toronto, ON

-

Contact:

Post

by zoob » Tue Jul 17, 2007 6:22 pm

It looks like they intentionally bowed the base. Did you lap it completely flat?

-

graysky

- Posts: 147

- Joined: Fri Sep 16, 2005 4:14 pm

- Location: My desk

Post

by graysky » Wed Jul 18, 2007 11:52 pm

Yeah I did and yeah a tech from TR told me they are convex by design since most C2D/C2Q chips are convex on the average. Lapped it completely flat and got the modest ~2 °C drop. If you look at the thread I referenced where I lapped the IHS on the chip, you'll see the largest drop occurred from doing that.

-

aristide1

- *Lifetime Patron*

- Posts: 4284

- Joined: Fri Apr 04, 2003 6:21 pm

- Location: Undisclosed but sober in US

Post

by aristide1 » Sun Mar 23, 2008 4:56 pm

Nice results, but how am I going to hold a Tuniq Tower and do that? I don't blood all over the place. Too many sharp points and edges.

-

ntavlas

- Posts: 811

- Joined: Mon Jul 16, 2007 2:35 pm

- Location: Greece

-

Contact:

Post

by ntavlas » Sun Mar 23, 2008 7:53 pm

Maybe you could try wrapping it with cloth.

As far as I know, flatness is far more important than smoothness, so it`s important to keep the movements as perfectly parallel to the glass (or whatever you use) as possible. It would help to start with thick sandpaper and slow, well controlled movements, concentrating all pressure at the base of the h/s.

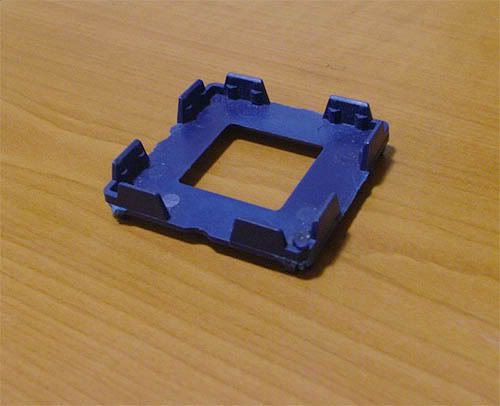

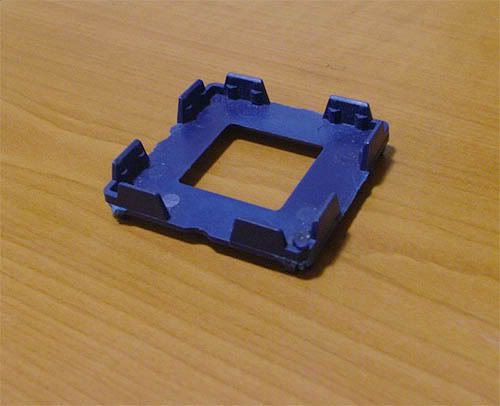

For anyone wanting to lap the cpu, a little plastic tray such as this helped me doing it while minimizing the risk of damage:

-

VanWaGuy

- Posts: 299

- Joined: Mon Sep 11, 2006 1:01 am

- Location: Vancouver Wa USA

Post

by VanWaGuy » Sun Mar 23, 2008 11:54 pm

Yes Ntavlas,

It seems to be almost unanimous opinion that flatness is very important, but there are some who conjecture that some shallow texture and the resulting increase in surface area might actually be a plus.

-

ntavlas

- Posts: 811

- Joined: Mon Jul 16, 2007 2:35 pm

- Location: Greece

-

Contact:

Post

by ntavlas » Mon Mar 24, 2008 12:23 am

I agree with that, the larger surface might benefit the tranfer of heat from metal to thermal paste (to me flatness doesn`t mean lack of texture). For this reason I would lap no further than 800grit. That should leave a texture similar to the machining done at the factory.

-

mcoleg

- Posts: 410

- Joined: Fri Feb 23, 2007 11:55 pm

Post

by mcoleg » Mon Mar 24, 2008 4:59 pm

aristide1 wrote:Nice results, but how am I going to hold a Tuniq Tower and do that? I don't blood all over the place. Too many sharp points and edges.

i actually did that to a tuniq - lots of hustle but not impossible. i had to do wet-sanding so it glides smooth and hold it by, well, the heat pipes and the base - there's just enough clearance to get a bit of a grip on the thing.

-

ame

- Posts: 488

- Joined: Tue Jul 10, 2007 10:35 pm

- Location: Israel

Post

by ame » Tue Mar 25, 2008 12:00 am

but is 4 hrs of work puls 22$ material worth the 2 c hit on temps? especially if the temps are low enough anyway considering your OC

-

VanWaGuy

- Posts: 299

- Joined: Mon Sep 11, 2006 1:01 am

- Location: Vancouver Wa USA

Post

by VanWaGuy » Tue Mar 25, 2008 5:35 am

That looks like you you have to answer for yourself.

-

graysky

- Posts: 147

- Joined: Fri Sep 16, 2005 4:14 pm

- Location: My desk

Post

by graysky » Tue Mar 25, 2008 12:01 pm

ame wrote:but is 4 hrs of work puls 22$ material worth the 2 c hit on temps? especially if the temps are low enough anyway considering your OC

Well the HS is just half the story. Have a look at the results I got after

lapping the IHS on my Q6600 as well

-

ame

- Posts: 488

- Joined: Tue Jul 10, 2007 10:35 pm

- Location: Israel

Post

by ame » Tue Mar 25, 2008 1:40 pm

Well the HS is just half the story. Have a look at the results I got after lapping the IHS on my Q6600 as well

Yeah, I remember readng your thread with the biggest gain achieved from lapping the Q6600. still 66 c isn't that high for an OCed Q6600 on load. I'm confident you are happy with the +- 10 c drop but a 2 c drop seems unjustified.

Nice work documenting the various stages and temps.

is the drop in temps after a while of use due to the lapping or does this allways happen?

-

graysky

- Posts: 147

- Joined: Fri Sep 16, 2005 4:14 pm

- Location: My desk

Post

by graysky » Tue Mar 25, 2008 11:44 pm

ame wrote:Well the HS is just half the story. Have a look at the results I got after lapping the IHS on my Q6600 as well

Yeah, I remember readng your thread with the biggest gain achieved from lapping the Q6600. still 66 c isn't that high for an OCed Q6600 on load. I'm confident you are happy with the +- 10 c drop but a 2 c drop seems unjustified.

Nice work documenting the various stages and temps.

is the drop in temps after a while of use due to the lapping or does this allways happen?

Well, I'm also not pushing it @ 9x333. If I want to run it faster, that 10 °C can be translated into higher vcore and higher fsb overclocks. It's all what you're after. I agree that lapping a HS alone might not be worth the effort, but again, it's 1/2 the equation for lowering temps through better contact. The CPU must be lapped as well for the best results.

That said, lapping the HS is good practice for the CPU. You can develop your technique on the more inexpensive component for example.

Does the temp drop without lapping? I don't think so. There is a break in period for AS5, but it's not gonna be 10 °C.

-

kieran45

- Posts: 38

- Joined: Tue Dec 18, 2007 1:57 pm

- Location: Melbourne, Australia

Post

by kieran45 » Wed Mar 26, 2008 1:18 am

Yeah, the lapping of the HS doesn't tend to give that big a change, usually 1-2 degrees. In general, most HS manufacturers tend to make the bases slightly convex, beacause the CPU is slightly concave. So when you lap the HS, the CPU is still concave, so the contact is often not much better. If you lap the CPU at the same time, both are flat, so much better contact, that's when you start to see much better temp drops.